May 11th, 2013

And now for something completely different:

This is a Sears tiller that a friend has stored in our barn. It has sat there for at least five years, but this spring, we had a use for it, so I decided to fire it up. Of course, you can’t expect a gasoline engine that has been sitting for five years to start up immediately. The first task I faced was to drain the carburetor. That should be easy: carburetors always have a little drain plug underneath the bowl. However, this carburetor is different:

This carburetor sits on top of the gas tank; you can see it just underneath the flat shiny pan and just above the black gas tank. “That’s odd” says I. There is apparently no way to drain the carburetor. If it has bad gasoline in it, along with varnish resulting from the gasoline decaying for five years, there’s no simple way to drain it.

“Oh well,” says I, “I’ll at least drain the gas tank.” Not so fast. There’s no hose running from the gas tank to the carburetor. In order to drain the gas tank on almost every engine on the planet, you disconnect the gas hose and let the gasoline drain into a container. But that’s impossible with this engine. “OK, so I’ll just tilt the damn thing over and drain the gasoline onto the ground.” It’s a filthy solution, but apparently the designers of this machine never considered the possibility that somebody might want to drain the gas tank.

It’s a good thing I drained the gas; it was really rank and could not possibly start an engine. Of course, the carburetor remained uncleaned, so I tried to figure out how to disassemble the carburetor. I’ve taken apart a lot of carburetors in my time, but this one appears way too tricky to disassemble. The critical parts are all jumbled together in a tight space; getting them back together might not be possible. I’d have to do without disassembling the carburetor.

At this point I’d like to digress about engine design. For more than a century, one basic layout has ruled. The gas tank is above the carburetor. The gasoline drains down by gravity into the carburetor. To drain the carburetor, you open the little drain plug in its bowl. To drain the gas tank, you disconnect the gas line from the gas tank to the carburetor.

However, some situations arose, mostly in automobiles, in which the gas tank cannot be above the carburetor. These cases required the addition of a new element: a gas pump. The pump sits below the gas tank so that it is automatically primed by gravity feed, and it pumps gas up to the carburetor. Such gas pumps have been around since the 1920s and they usually use a simple cam system. Such pumps are quite robust.

But the geniuses who designed this engine didn’t want to use such a pump; apparently it’s too low-tech for them. Instead, they came up with a new design for a pump. This pump uses a membrane that is exposed to the main intake airway to the engine. As the engine runs, that airway undergoes rapid changes in pressure. The little membrane is thus pulled and pushed, pulled and pushed, with each cycle of the engine. On the other side of the membrane, the changing air pressure flips two other little membranes back and forth, alternately sucking gasoline out of the tank and shoving it into the carburetor.

Apparently it never occurred to the design engineers that somebody might keep a tiller for more than, say, five years, because the pump only works when the membrane is fresh and supple. As it ages, it grows stiff and the rubber frays. Which means that the carburetor won’t get any gas and the engine won’t run.

But this barely plumbs the depths of their idiocy: since the pump isn’t primed by gravity, the only way it can prime is if the engine turns over. Thus, when you first pull it out of winter storage, it will not start. You have to pull the starting cord over and over to get the pump primed, then over and over some more to get some gasoline into the carburetor.

Yet all the pulling in the world wouldn’t get my engine to start, so I came up with a clever idea: I removed the air cleaner (both photos show the engine without the air cleaner atop the carburetor). Then I splashed some gasoline straight down the throat of the carburetor. The first few pulls only served to spit gasoline back out the throat, at me. However, after a few pulls, the mixture was right and the engine would start, run for about five seconds, and then die.

You might think that having the engine run at full speed would be enough to get that pump working. You’d be overestimating the intelligence of the Sears engineers.

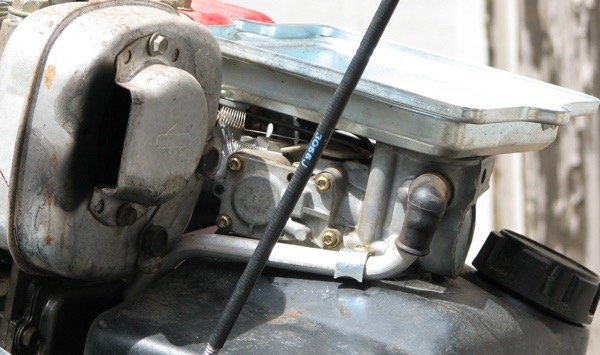

I decided that I need to check out the gas pump myself. Enter more idiocy. Here’s the carburetor up close:

The exhaust muffler is on the left, the gas tank cap is on the right, the air filter holder pan is at the top, and the carburetor is the stuff in between all these. I direct your attention to the doodad dead center, a plate held in place by four bronze screws. That’s the gas pump. Those four screws are not conventional screws. No, the engineers at Sears decided that we’re too dumb to remove the gas pump, so they used star-screws, which require a special tool. Fortunately, I have that tool.

But the Sears engineers are done yet. They cleverly mounted the throttle line (that’s the black thing in the foreground running diagonally across the picture) so that it gets in the way of any tool you attempt to use to turn those screws. They could have moved it two inches in any direction and eliminated that problem, but no, why should hoity-toity design engineers worry about repair problems? Their engine is so perfect that it’ll never need repairs anyway, right?

One last obstacle: that bright tube running just underneath the carburetor, terminating in a black rubber boot: that’s the crankcase exhaust pipe. It vents air from the crankcase back into the carburetor so that the heavy hydrocarbons released by the oil are burned, so they don’t contribute to smog. That little pipe is positioned in such a way that it is impossible to get a tool directly onto the lowest star-headed screw. You have to come in at a slight angle, which of course makes it a trickier proposition and can easily result in damage to the screw head if you’re not careful. Thank you, engineers; you needed only move that pipe or that screw a few millimeters, but no, you were too busy to do that.

All this contrasts markedly with the design of Japanese motorcycles or German cars, both of which I’ve worked on. It’s clear from the layout that the engineers were careful to insure that all parts were optimally accessible. I had come to take that kind of care for granted.

Over the years, I’ve worked on lots of different engines, and I can state with certainty that this is the most idiotically designed engine I have ever seen. A big fat Skunky to Sears for this disaster on wheels.